Forums RWI and Reddit have universally acknowledged the clean factory. There is no question that the clean factory Rolex has the best clone workmanship and materials, even if some of the experienced Rolex jewelers can’t spot it. So, it is valuable to have a Clean factory ROLEX. You can even repair parts alternatives for your genuine ones.

So the only question is how and where to buy a real and Latest version from Clean Factory Rolex. We have a headache because many manufacturers or middle resellers created websites using our name to sell their watches. Just cover our stick label.

They may sell cheaper because of the materials and movement difference from our clean factory, But at first sight, they may look the same. But Time will tell everything. Bad timekeeping(second hands or repaired movement, unknown low quality), Lost waterproof(Poor workmanship or assembled by machine), noticeable scratches(Not solid 904L steel via DLC ), gold fade away(NOt real gold wrapped), bezel and hands turn to tarnish and get old soon(not coated by the real platinum)

To protect our reputation, we created www.realcleanfactory.com; the guarantee is that the real Clean Factory Rolex is the latest version and brand-new clone movement under a two-year warranty.

Sharing the news or any upgraded information here.

Welcome the wholesaler and reviewer. We can take actual pictures of the details and videos after you order. Then, you can pass these pictures to some of the professional forum moderators to verify that this is the best quality version. Also, we can accept payment by Paypal(No other sellers Dare to use this payment option), which means we are confident with our masterpiece and will always be responsible honestly for long-term business.

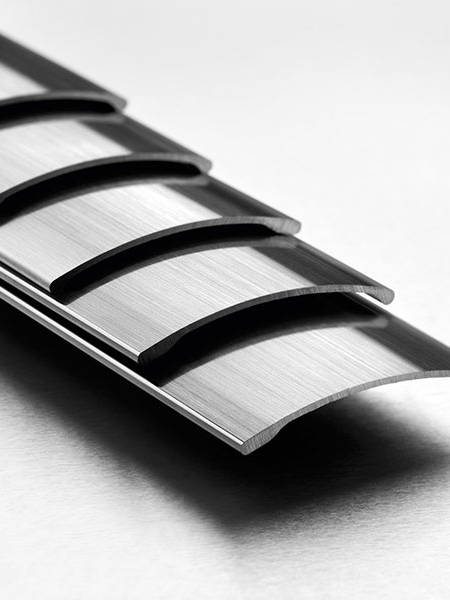

Our clean factory has constructed the perfect Clone, made in 1:1. A genuine watch was used as a sample and was completely disassembled for cloning, so all parts are interchangeable with genuine. This is achieved by completely disassembling the genuine watch and cloning all parts using the most advanced CAD/CAM, modular molds, and CNC Laser Machines. Our Clean factory Rolex compares favorably with the Swiss level of quality and craftsmanship.

〰

904L Stainless Steel

Every watch case is made from the highest-quality 904L stainless steel, it has outstanding overall corrosion and sensitization-resistant properties, making it the most suitable choice for providing the best-quality casing.

The Rolex cases include the serial and model numbers on the lugs, which correspond to the genuine. From no pinholes on the watch cases to thicker hands on the Yachtmaster, our watches are simply heads and shoulders above the competition—threaded screws link our bands. Threaded screws link genuine Rolex bracelets together. All other replica Rolex watches has a pin instead of a screw. It is much more expensive to thread the interior of a link and even more expensive for the jeweler to insert the screw manually. The links are also much easier to adjust.

You will also find on our Clone whatever markings, engravings, or features a genuine watch has.

〰

Solid High-Tech Ceramic

Not only does a Cerachrom bezel look great on a watch thanks to its shiny appearance but it is also practical due to its resistance to scratching and fading. scratch-resistant Cerachrom insert in ceramic, numerals, and graduations coated in platinum

〰

Real 18K Gold Heavy Wrap

Our Clean factory Rolex gold watches have real 18K heavy wrap gold parts on the middle link, crown, and bezel. The all-gold watches now come in heavy wrap 18K Gold. This results in a watch that tests positive for 18K gold (since the layer is 7 times thicker than simple gold wrap) with Titanium Nitride layers in the base and real 18k Gold layers on top. The watch, therefore, looks and feels just like the real thing. It can even be polished without fading. This method saves thousands of dollars because you are only paying for a layer of 18K gold instead of the whole weight of the band and case.

Heavy Gold Wrap Solid 18k Gold & Titanium Nitride (TiN)

Now featuring on all our “full” gold models is a revolutionary gold technique using solid 18k gold and titanium nitride offers 100x more durability in comparison to gold wrapped. Space age gold-colored titanium nitride is put down first as a “rough” deposit, and then layer upon layer of solid 18k gold is fused into the valleys of the rough surface. The same solid gold content is used as in previous techniques, but it is now protected by the “peaks” of color-matched TiN, so it doesn’t wear away.

Although this method is more expensive to produce, it provides an incredibly long-lasting, perfect appearance that is unmatched by any other gold plating method.

〰

DLC Coating

Physical Vapor Deposition (PVD) is the method used to deposit thin material layers by vapor condensation in a high-temperature and vacuum environment. DLC or Diamond-like carbon coating is the highest quality in the black coating, the most durable, and the hardest to scratch. The coating is done by bonding high-energy precursive carbon rapidly cooled down on the surface. It is very similar to the process of making synthetic diamonds. Not only is the process similar, but the carbon coatings have the same attributes as diamonds since they are extremely hard and very resistant to scratches. In other words, it is perfect for making metal surfaces more durable.

There are a few key characteristic of DLC, which has helped it to supplant the use of PVD as a cosmetic coating for fine timepieces:

IT’S HARDER

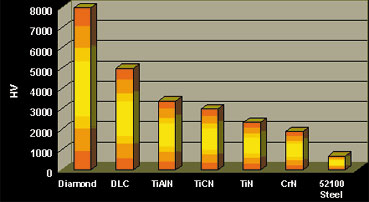

DLC is an extremely hard coating. The following shows the comparative surface hardness of various materials, using the Vickers of Hardness scale:

DLC Hardness Chart

DLC Coefficient Of Friction Chart

In terms of relative hardness, DLC, at 4000+ HV is:

– About 5X as hard as stainless steel

– About equal to sapphire

– About one-half as hard as a diamond

– Significantly harder than other PVD coatings

IT’S EXTREMELY WEAR-RESISTANT

Because of its durability, DLC is used as a tribological coating for machine tools such as drill bits, saws, and dies. DLC coatings provide superior durability and wear resistance when used on a watch.

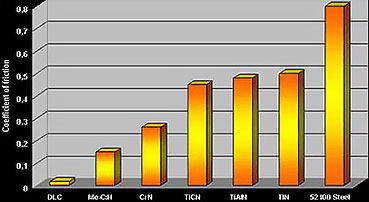

IT HAS A LOWER COEFFICIENT OF FRICTION

DLC is quite slick. The following chart compares the coefficient of friction of DLC and other materials:

The low-friction attributes of DLC help to increase the durability of the coating when used on watches. Glancing blows against a hard surface, which may dig in and damage regular PVD coating, and they are more likely to simply slide over across the surface of a DLC-coated case. Simply stated, it’s just more challenging to damage a DLC coating. These characteristics and the beauty of DLC have helped it grow in popularity as a hard surface coating for fine watches.